From: "Daniel Denson"

To: "Dave Mainwaring"

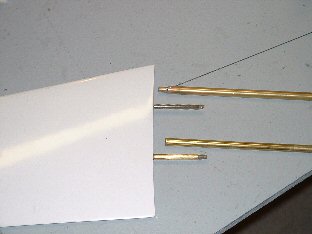

Subject: star45 photos

Date: Sun, 11 Feb 2007 20:01:39 -0600

Construction photographs, articles about the Star 45. How To Build A Wooden Star45 R/C Sailing Model! Browse http://woodstar45.blogspot.com/ Based on the International Star Boat this semi-scale Star45 can be scratch built by novice or seasoned skipper. Easily radio controlled and large enough to see out on the water this is a classic model model built by hobbyists for over thirty years! Dave Mainwaring's Knowledge Network Blog